Life Cycle of Lithium

The Life Cycle Assessment (LCA) is an environmental management tool that objectively, methodically, systematically and scientifically analyzes the environmental impact generated by a process or product during its entire life cycle.

This is a tool for comparison and not for absolute evaluation. It helps decision-makers to review the main environmental impacts. Since LCA is a data-intensive method, the availability of adequate and reliable information is a fundamental issue and, therefore, various databases have been developed internationally, such as GaBi, ecoinvent, IBO and others.

Following the basic principles of life cycle assessment, calculations are based on ISO 14040, 14044 or 14067 and the PAS2050 standard related to the specific product. The Greenhouse Gas Protocol of the Intergovernmental Panel on Climate Change (IPCC) and the recommendations for calculating emissions according to their global warming potential also apply.

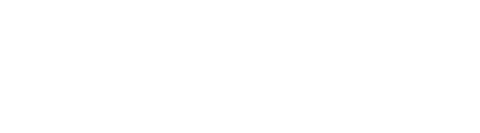

Fig. 1: steps of an LCA. From the International Organization for Standardization (2006) Environmental Management – LCA – principles and framework. ISO 14040. Geneva: ISO.

LCA framework

The steps necessary for the analysis are:

● Gate to gate: contemplates only the activities or the production process of the company to which it applies.

● Cradle to gate: considers from the extraction and conditioning of raw materials to the production process of the company.

● Gate to grave: reviews the company’s production process until the management phase of the waste that the product generates.

● Cradle to grave: analyzes from the conditioning of raw materials to the final treatment of waste through recycling or other alternatives.

● Cradle to cradle: studies the complete life cycle of the product. It goes from the conditioning of raw materials until the product, after being out of use, is reintroduced in the same production process or in another.

LCA for Lithium Carbonate

Values for Lithium Carbonate differ according to databases:

From Cradle to Gate datasets

| Data base | Ton CO2/ton Li2CO3 |

| Ecoinvent 3.1 | 2 |

| GREET 2016 | 3.3 |

LCA for Lithium Hydroxide:

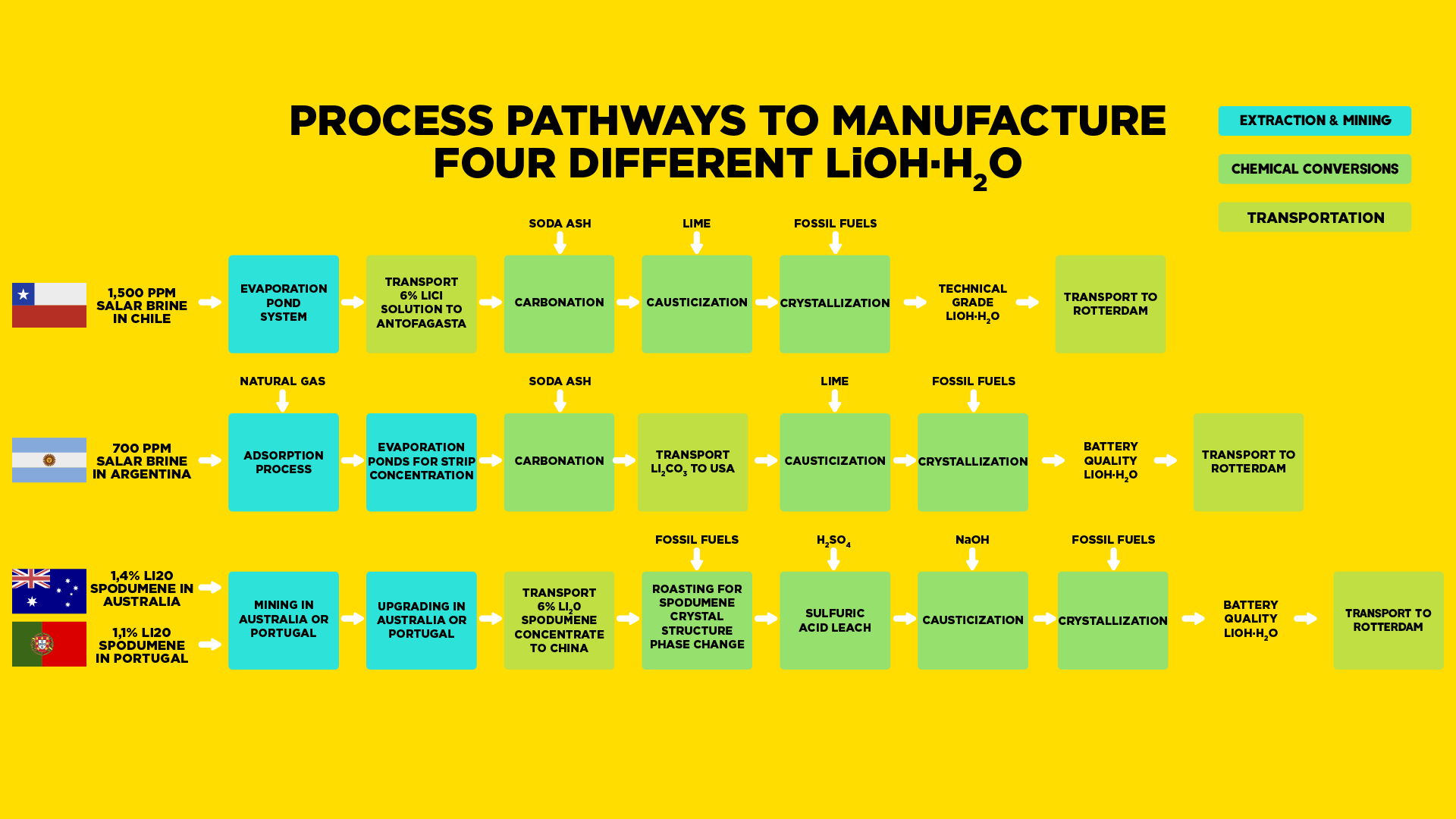

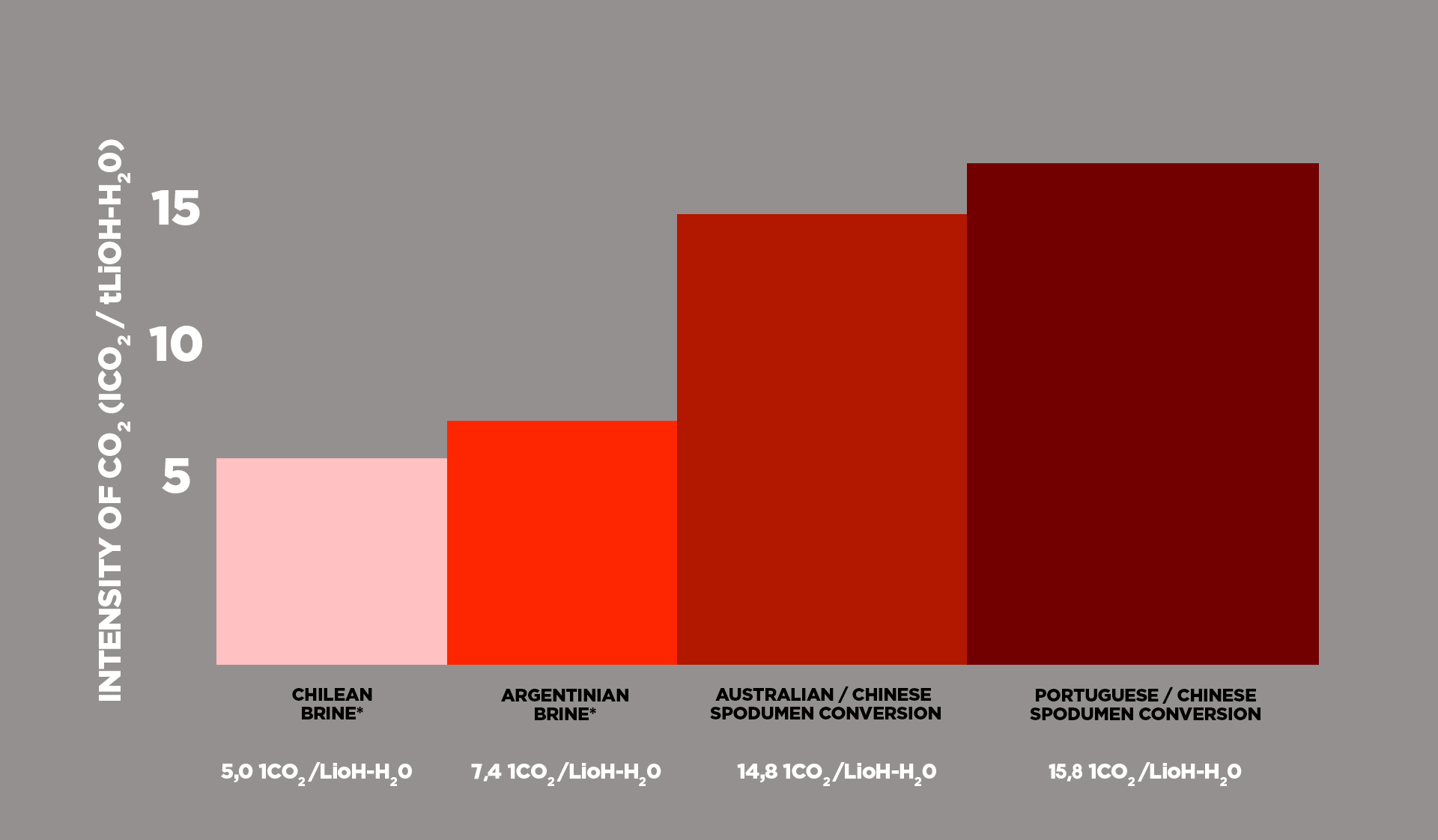

LiOH • H2O is produced in different ways, by different companies, from different natural resources, which means that there is not a single intensity of production of LiOH • H2O CO2, but a range for a variety of LiOH • H2O products offered by companies that carry out operations. Minviro drew up an LCA for lithium hydroxide from dissimilar processes.

RESULTS

LiOH • H2O produced from brine has the lowest CO2 levels on the market today.

On the other hand, the levels of CO2 from the processing of spodumene concentrate in China is the highest in the world.

LITHIUM LIFE CYCLE

Committed to caring for the environment, at SQM we work on production processes under strict national and international standards. For this reason, one of the most important actions of the operation is to measure the impact of the company’s lithium production, both on the environment and on communities and areas of operation. It is the Life Cycle Analysis, an environmental management tool that objectively, methodically, systematically and scientifically analyzes the environmental impact generated by a process or product during its entire life cycle.

An important item that is measured is the carbon footprint of the operation and its products. In the case of lithium, the process is measured under strict, demanding and prestigious international standards, under the norms ISO standards 14040 and 14044. Currently, the company was able to measure under three measurement variables, based on energy use, water consumption, and CO2 from operations; It is a study carried out by Afry, the results of which are used to develop different processes in SQM’s own operations and to communicate them, as the case may be, to different stakeholders. The LCA ISO 14040 and 14044 standards are applied for the calculations of these studies.

The study provides a document that allows defining the levels of CO2, energy and water consumption in order to keep the emissions of the operation and the life cycle of the product up to date and controlled. This method allows calculating the contribution of emissions for the manufacture of lithium ion batteries and cathode materials. There is also a strength that is reputational, since it is a laboratory in the United States, which depends on the Department of Energy of that country, which provides support and credibility to the information that emanates from its studies.

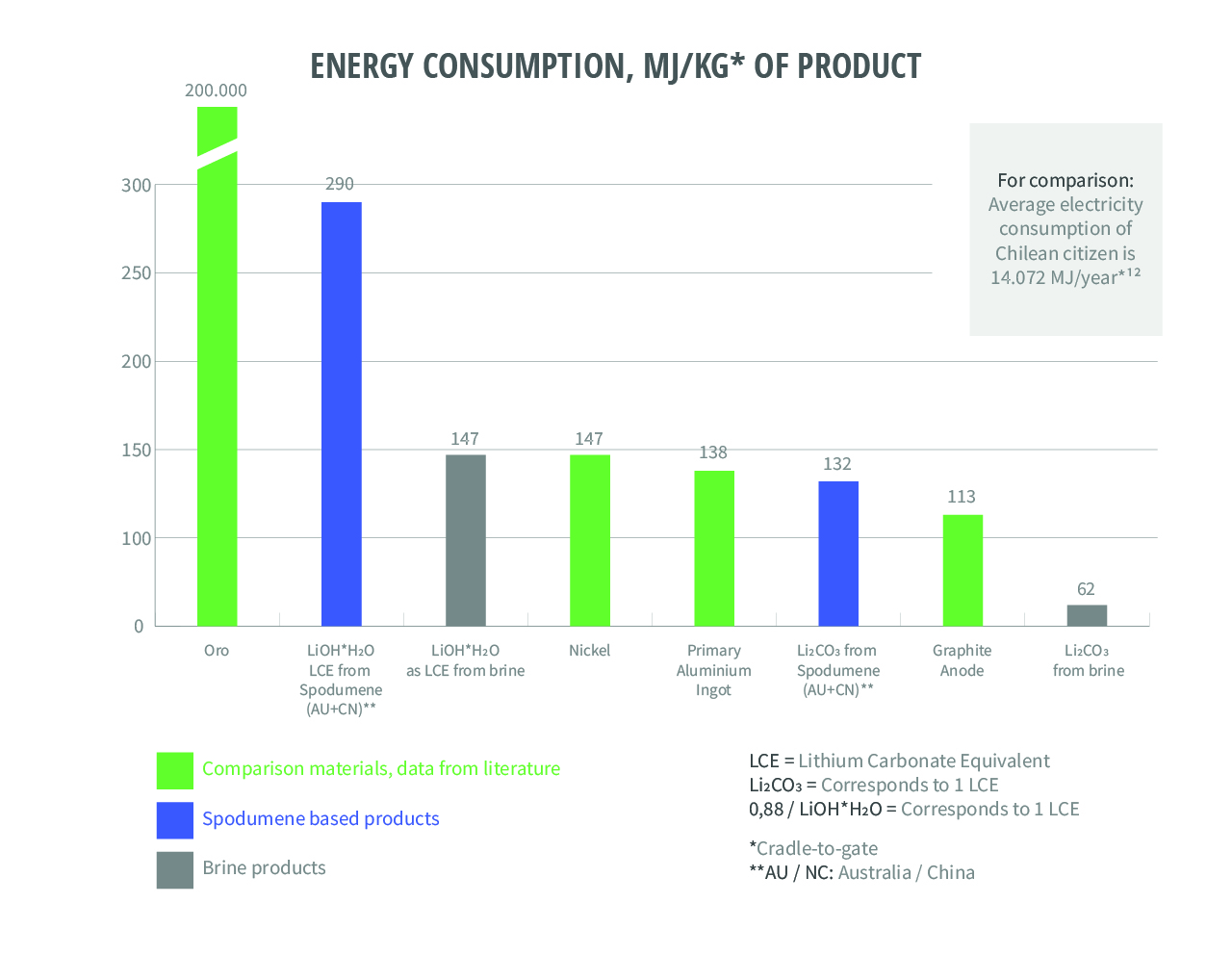

ENERGY CONSUMPTION

SQM’s lithium production process has the lowest energy consumption compared to spodumene-based lithium production. This statement is based on the fact that during 2018 approximately half of the world’s lithium production came from spodumene and the other half from brine, as is the case of SQM Lithium, and according to a life cycle analysis carried out by SQM and the consulting firm Afry, SQM has low energy consumption.

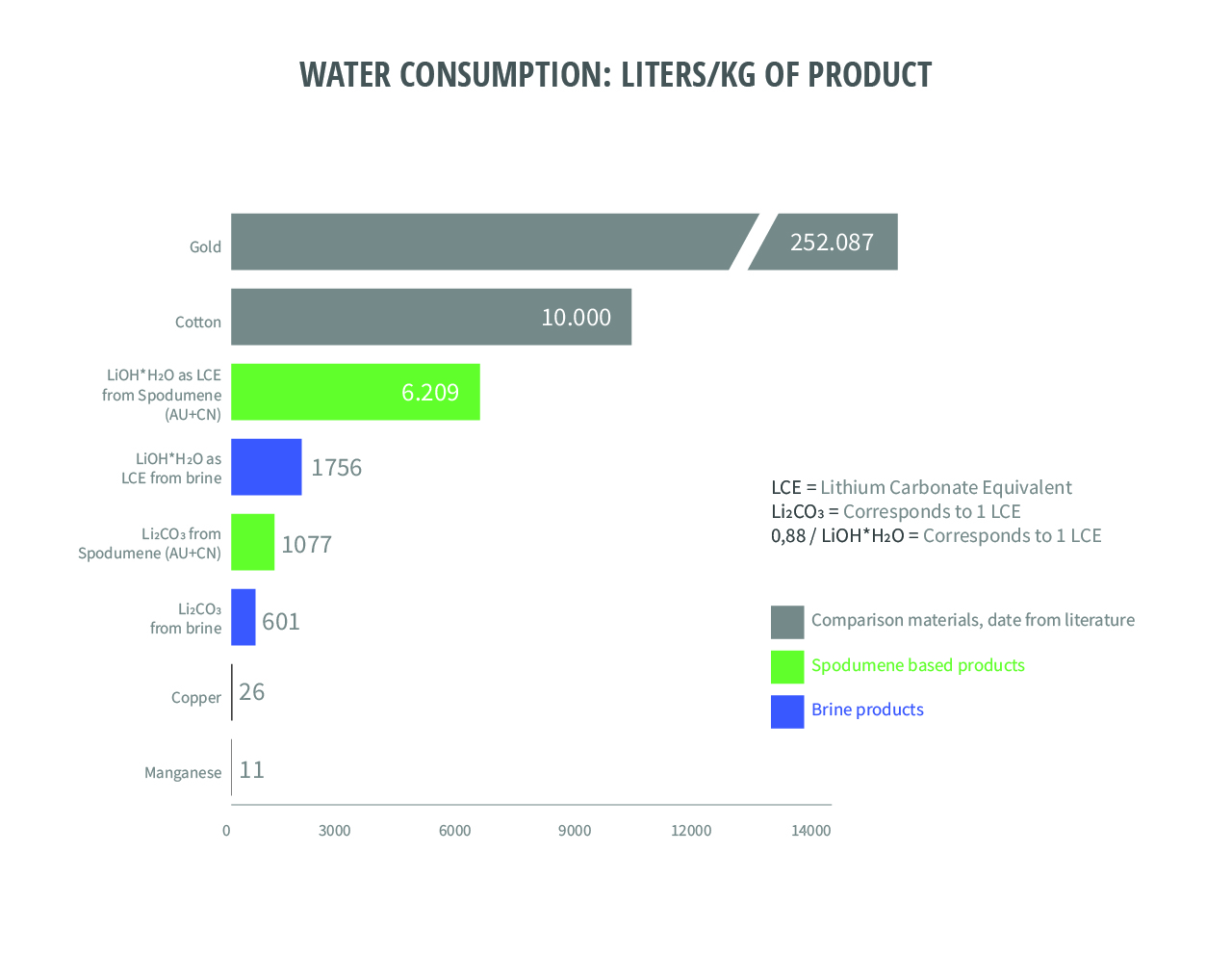

According to the SQM Lithium Life Cycle Analysis provided by AFRY, the water footprint in brine production is significantly lower than in Australian refined hard rock (spodumene) production in China. For example, SQM requires approximately 22,5 liters of water per kilogram of lithium carbonate for the entire process if the water consumption of the supplied products (door to door) is not included. In the LCA, the water consumption was calculated by SQM (cradle to customer) according to ISO 14040 and 14044.

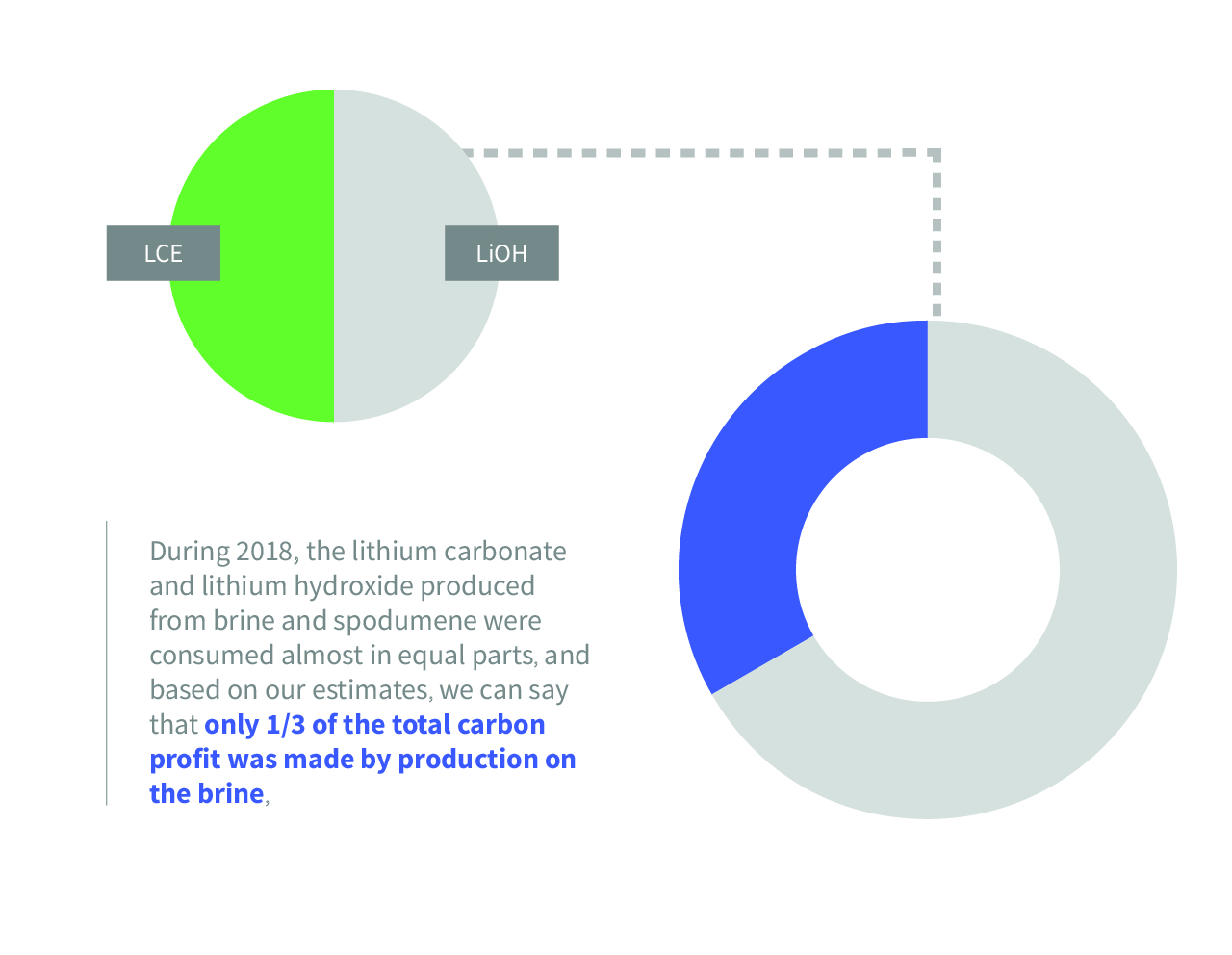

During 2018, lithium carbonate and lithium hydroxide produced from brine and spodumene were consumed almost in equal parts and, according to our estimates, we can say that only 1/3 of the total carbon footprint was generated by the production based on brine such as SQM Lithium. That means SQM’s lithium has one of the lowest carbon footprints in the world.

* Afry SQM study (2018 world data). The comparison was made with Australian spodumeno, refined in China.

* LCA: Based on information from SQM.

Sources:

https://www.sqmlithium.com

https://www.gabisoftware.com/fileadmin/Documents/GaBi_Modelling_Principles_2018.pdf

Takano A, Winter S, Hughes M, Linkosalmi L, Comparison of life cycle assessment databases: A case study on building assessment, Building and Environment (2014), doi: 10.1016/j.buildenv.2014.04.025.

The Life Cycle Energy Consumption and Greenhouse Gas Emissions from Lithium-Ion Batteries – A Study with Focus on Current Technology and Batteries for Light-duty Vehicles. IVL Swedish Environmental Research Institute 2017

Grant A, Deak D, Pell R. The CO2 Impact of the 2020s Battery Quality Lithium Hydroxide Supply Chain. Minviro, January 2020.